Client

University of Maryland Medical System

Designer

Wilmot Sanz

Location

Largo, Maryland

Size

620,000 Square Feet

Completion Date

2020

Delivery Method

Construction Manager at Risk

e029.jpg?itok=606phdvm)

cb4d.jpg?itok=FvBIyayK)

9b09.jpg?itok=mrXd0lff)

ebd0.jpg?itok=B5TkrOD5)

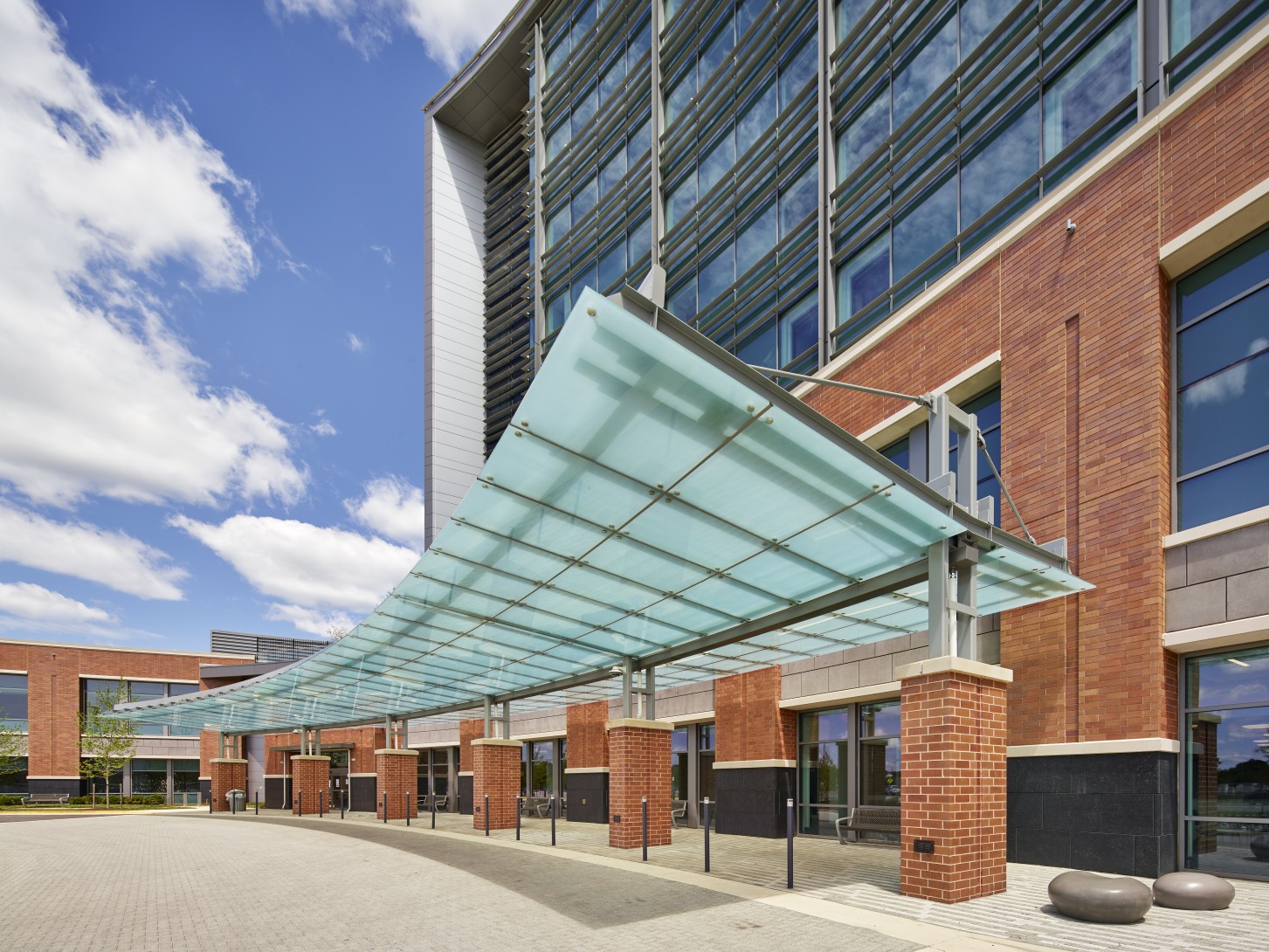

The University of Maryland (UM) Capital Region Medical Center is a 620,000-square-foot hospital replacing a 75-year-old facility in Prince George’s County, Maryland.

The 11-story patient tower features 205 private patient rooms, 45 emergency room treatment bays, 20 observation rooms, and eight operating rooms. The medical center provides spaces for clinical services, including emergency care, neonatal intensive care, behavioral health, neurosciences, orthopedics, labor & delivery, critical care medicine, and Level II trauma.

Seamlessly Meeting Medical Equipment Specifications

Ensuring that the new hospital spaces were constructed to accommodate the requirements for major pieces of medical equipment was a key construction challenge. Clark worked hand-in-hand with the UM Medical System to identify medical equipment vendors early in the project. The team met with key medical staff and the nine equipment vendors to review designs and make necessary room adjustments so that equipment would fit seamlessly into the new spaces. These discussions were vital to construction of the laboratory, MRI, CT, and hybrid operating room spaces.

The team also studied mock-ups of operating rooms, patient rooms, and treatment bays to finalize details of these critical spaces before construction, which was key to managing the project’s aggressive schedule.

Prefabricating and Installing the Central Utility Plant

The coordination and installation of the medical center’s prefabricated central utility plant (CUP) proved to be one of the project’s largest and most complex challenges. The CUP was prefabricated in North Carolina and contained essential mechanical, electrical, and plumbing equipment for the facility. Clark built the foundation to accommodate the structure, which required detailed coordination.

Despite the need to reduce daily manpower on the project during COVID-19, the team was able to deliver the facility ten days early through early coordination and excellence in project management, including switching the millwork and flooring subcontractors to night shift in order to minimize the number of individuals on site.

BIM Modeling Used for Helipad Clash Detection

As a Level II Trauma Center, the facility also had to be well-equipped for any emergency scenario and included two helipads on the roof of the hospital. The helipads had a unique configuration and required coordination with both the building structure itself and the two air handler units on the roof. The team leveraged Building Information Modeling (BIM) technology to model the placement of the air handler units, lights, and other equipment and identified several conflicts, including concrete columns blocking the access door. Following adjustments and successful construction of the helipads, the team performed an innovative helipad foam test to confirm the fire-fighting capabilities of the pad in case of any emergencies.

For Prince George’s County, By Prince George’s County

Participation from small, local, county-based, and minority businesses throughout the construction process was a priority for all project stakeholders. In collaboration with S.M. Jackson Government Business Solutions, LLC, Clark’s small business compliance advisor, Clark awarded $30.9 million in contracts to County Based Minority Business Enterprises (CBMBE) for a total percentage participation of 13.5%, exceeding the goal of 10%, as well as a total of $177.9 million, or 77.86% CBMBE, Minority Business Enterprises (MBE), and Locally-based Business Enterprises (LBE) vendors, surpassing the goal of 25%.

Awards

2021 ABC of Metro Washington Excellence in Construction Award (Healthcare)

2021 AGC of DC Washington Contractor Award (Healthcare)

2021 ENR Mid-Atlantic Best Project Award (Healthcare)

.jpg2570.webp?itok=4PCT5dYQ)