Preparing for the Breakthroughs of Tomorrow at MedStar Georgetown

November 21, 2024

MedStar Georgetown University Hospital faced the pressing challenge of serving a growing and aging population in the Washington, DC area. It was clear updates were required for the facilities to support emerging medical technologies and deliver the latest standards of patient care. Recognizing the need for modernization, MedStar collaborated with Clark and project partners to design and build a replacement facility that meets current and future patient needs within the constraints of a compact urban site.

Following years of strategic collaboration, operational planning, design, and construction, the new Verstandig Pavilion at MedStar Georgetown University Hospital (MGUH) officially welcomed its first patients in December 2023. The state-of-the-art, 475,000-square-foot medical center features 156 patient rooms, 31 operating rooms, a new emergency department, surgical prep and recovery bays, a landscaped courtyard, and a rooftop helipad, as well as a 310,000-square-foot, three-story, below-grade parking garage.

In addition to serving a new standard of care designed to treat the whole patient, the Verstandig Pavilion provides an elevated learning experience for medical and nursing students to practice clinical care and conduct research in a hospital setting with the most advanced technology and systems. With comprehensive flexibilities designed into the new facility, functions can be adapted as medicine continues to evolve, meeting the region's healthcare needs for decades to come.

Image

Logistics Take Center Stage on Congested Site

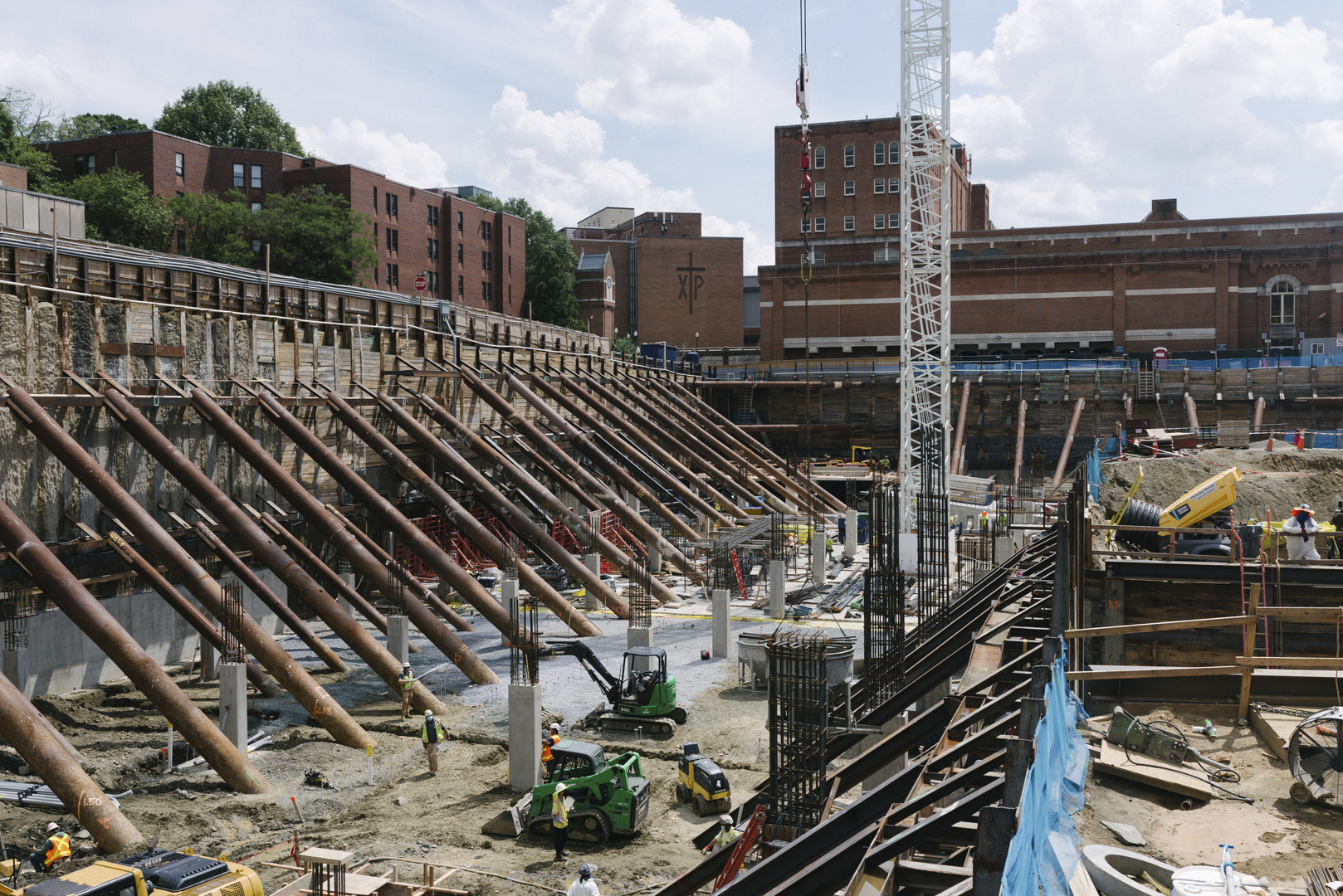

Located on the edge of the Georgetown University campus, the pavilion is bordered by a major city throroughfare, a student affairs building, a parking facility, three academic buildings, and an existing hospital building, all needing to remain fully operational throughout construction.

From the beginning, Clark and project architect HKS/Shalom Baranes Associates Joint Venture created a BIM model to profile anticipated rock and existing utilities onsite based on preliminary information and an initial geotechnical report with limited borings. Before construction, the team relocated over 17,000 feet of utilities which fed MGUH and Georgetown University campus buildings and ran directly through the site. As the design progressed, information from additional borings at caisson locations was added to the BIM model, which was used to develop a cost model for the deep foundations work and an excavation plan for the project.

With over 1,000 piles to install for the internally braced support of excavation, the model gave the team flexibility to revise and resequence the excavation plan as necessary before fieldwork commenced. This ultimately minimized the impact of the site’s complex conditions on the project schedule.

Image

Strategic Use of Prefabrication Meets Client Goals

The project team’s strategic decision to use multiple prefabricated building elements delivered exceptional quality while reducing the tight site's noise levels, traffic, and parking needs. A key benefit realized by this approach was having offsite space to construct early mockups of operating room ceilings, patient rooms, electrical rooms, and bathroom pods during the excavation phase. These mockups enabled the client to review planned interior spaces much earlier than usual in the construction process, expediting approvals of these elements and saving six weeks in the project schedule.

The decision to prefabricate operating room ceilings also supported Medstar Georgetown’s priority to provide best-in-class healthcare by supporting future upgrades in medical technology. The ceilings' steel supports were designed to accommodate maximum equipment needs, facilitating future installations of new operating room technology. This strategic design allows operating rooms to be offline for just a few days rather than several weeks for equipment replacement.

Image

Pavilion Delivers New Standard of Patient Care

Focused on transplant, orthopedics, and neurosciences, the spacious operating rooms give surgeons 4K visualization for robotic and minimally invasive surgery. Interactive touchscreens allow surgical teams to consult with global experts without leaving the patient’s side. The Transplant Center for Children is the only facility of its type in the Washington, DC area. In addition, the emergency department doubled its capacity to serve the more than 36,000 patients who use the hospital as their primary source of medical care and treatment.

The Pavilion also includes a new state-of-the-art intraoperative MRI system, the first in the Washington region. The magnet is installed along rails, allowing clinicians to perform real-time imaging without transferring patients outside the operating room.

Through these innovative medical technologies and an unwavering dedication to patient care, the Verstandig Pavilion was built to deliver the highest quality treatment for generations to come.

This article originally appeared in the Fall 2024 issue of Superstructure, a Clark publication about our projects and teams. Click through to find all issues of Superstructure.